our services

We're dedicated to helping you craft exceptional retail marketing strategies to significantly boost your product sales..

CONCEPT AND DESIGN

PROTOTYPES

PRODUCTION

FULFILLMENT

CONCEPT AND DESIG-01

In the world of retail, you have just 10 seconds to capture a customer's attention. That fleeting moment could turn a passerby into a loyal customer if you can entice them to pick up your product. That's where we come in! Our Packaging Engineers are experts at overcoming this challenge and will collaborate with you to design a solution that breaks through the 10-second barrier. Our goal is to help you develop effective retail marketing strategies that drive your product sales.

We recognize that there's no one-size-fits-all answer in point-of-purchase displays. That's why our solutions are crafted to be as distinctive as your brand and products. By understanding your specific needs, we work together to transform our creative ideas into impactful displays. We're confident that the results will exceed your expectations. So, are you ready to elevate your brand?

Wondering how to discover the perfect solution for your needs?

With a design that's ready for printing

With a design that's ready for printing, we can turn your creative vision into a real, physical product using your artwork. We'll provide you with a detailed prototype to review, and we may also offer tailored recommendations from our experts to optimize the final display. This ensures that your cardboard display not only meets but exceeds expectations, standing out effectively in the retail environment..

Curious about how your final display will turn out?

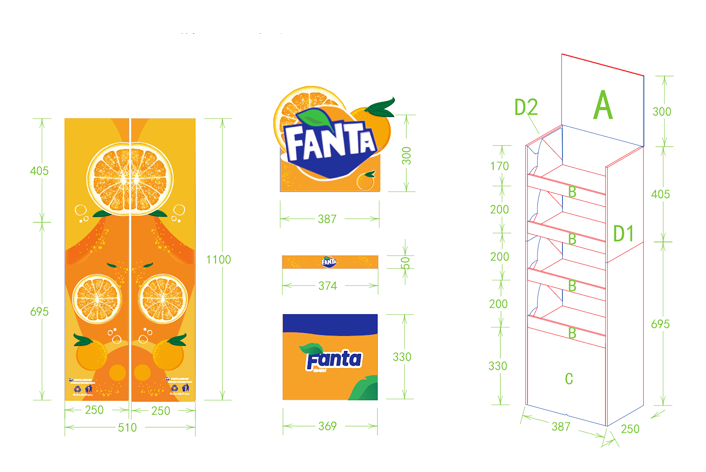

Explore our extensive online catalog, featuring hundreds of display styles that are sure to catch your eye. If you have your own ideas or sketches, our skilled 3D designers can create a detailed 3D rendering based on your concepts. This allows you to visualize how your custom cardboard display will look and function in real-life settings, ensuring it perfectly aligns with your vision and stands out in the market.

Not sure where to start?

Not sure where to start? No problem! Just share your product details with us, and we'll craft a tailored solution that fits your needs. Our team will provide expert recommendations to create a custom cardboard display that effectively showcases your product. Whether you have a specific vision or need guidance, we're here to help you develop an impactful display that stands out in the market.

Structural Design & Graphic Design

With extensive experience in crafting point-of-purchase (POP) displays and retail packaging, our structural design team has successfully implemented designs across a diverse range of industries. The Grand Fly design team now offers expert solutions to both renowned international brands and leading Chinese enterprises. We specialize in integrating innovative structural and graphic design elements to create impactful displays that enhance brand visibility and drive consumer engagement.

PROTOTYPES-02

Structural Design

Our structural design team brings years of expertise in crafting cardboard point-of-purchase displays and retail packaging for a diverse range of uses. We're committed to not only making your display stand out with unique and innovative structures but also ensuring it's cost-efficient.

At Grand Fly, we strive to design displays that are both visually striking and economically viable. Leveraging our extensive experience with various display types, we focus on building structures using the most cost-effective methods. This approach helps us reduce our clients' expenses while also benefiting the environment. We achieve this by minimizing raw material usage and substituting plastic components with recyclable alternatives, aligning with our commitment to sustainability.

01

Fast Sampling

Our plain white samples can be completed within 1-2 business days, while color samples may take 2-3 business days. For more complex designs or specific requests, we work efficiently to deliver your samples as quickly as possible, ensuring you have the accurate representation of your cardboard displays ready for review.

02

Visualize Your Design

At One Plus Display, our Graphic Team specializes in bringing your unique ideas to life. Before we create a physical prototype, we provide a 1:1 scale 3D rendering of the display. This detailed visual helps you see exactly how the finished product will look, making it easier for international clients to quickly approve designs. This streamlined process ensures that your cardboard displays are accurately represented and approved, accelerating the path from concept to creation.

03

No Charge for Samples

We offer a comprehensive range of services including structural design, digital color printing, tooling, sample creation, and flat packaging-all at no additional cost. Enjoy complimentary design services, free tooling, and no charge for samples. Our goal is to provide a seamless experience, ensuring that you receive a high-quality prototype without any extra fees, making it easier for you to visualize and refine your cardboard display solutions.

04

PRODUCTION-03

Production

At One Plus Display, we handle the entire manufacturing process in-house, ensuring the highest quality standards and maximum efficiency. Our state-of-the-art facilities include our own offset printing presses, large-format automatic laminating machines, and precision die-cutting equipment. By controlling every aspect of production, we maintain tight cost management and accelerate the turnaround time for your displays and packaging. This allows us to deliver exceptional products faster than our competitors, all while keeping costs under control and maintaining superior quality.

Quality Reflects Our Commitment to Clients

We are dedicated to the principle that "Quality Reflects Our Commitment to Clients." By adhering to the ISO 9001 quality management standards, we have established a robust quality control team. This team oversees not just the product quality but also the efficiency of our production processes. Our rigorous approach ensures that every cardboard display meets the highest standards, guaranteeing that our clients receive superior products and services.

Our equipment

Printing Center

Surface Treatment

Mounting

Die-Cutting, Folding & Gluing

Digital Center

Testing Instrunment

Our State-of-the-Art Printing Center

At our advanced printing facility, we bring your cardboard display designs to life with precision and efficiency. Our Printing Center features top-of-the-line equipment to ensure the highest quality output:

1×Roland 900 5C Offset Press, with a sheet size of 1200×1620 mm, perfect for handling large-format prints with stunning detail and vibrant colors.

1×Roland 700 5C Offset Press, featuring a sheet size of 740×1040 mm, ideal for high-resolution printing on a variety of substrates.

1×Kodak Trendsetter Q1600 CTP, with a sheet size of 1325×1650 mm, providing precise computer-to-plate imaging for superior print quality.

1×Paper Reel Sheeter, capable of handling sheets up to 1700 mm in width, ensuring smooth and efficient paper processing.

1×Paper Cutter, with a cutting capacity of 1680×1680 mm, for accurate and clean cuts on large sheets.

This combination of cutting-edge technology allows us to deliver exceptional results on every project, ensuring your cardboard displays are both visually striking and durable.

Surface Treatment

To ensure the highest quality of our cardboard displays, we employ advanced surface treatment technologies. Our facilities are equipped with a range of cutting-edge equipment, including a paper cutter with a sheet size of 1680×1680 mm, which allows us to precisely cut materials to meet your specifications. We also use an auto laminating machine with a sheet size of 1300×1620 mm to provide a durable and professional finish to our displays. Additionally, another auto laminating machine with a sheet size of 1080×1450 mm is utilized to enhance the surface treatment, ensuring that each display is not only visually appealing but also resilient and long-lasting. These sophisticated processes enable us to deliver high-quality, custom cardboard displays that stand out in the market and meet your exacting standards.

Mounting

At one plus display, we pride ourselves on precision and efficiency in every step of creating exceptional cardboard displays. Our advanced setup includes state-of-the-art equipment to ensure flawless results. For mounting and assembly, we utilize two high-performance corrugated mounting machines: one with a sheet size of 1650×1650 mm and another with a sheet size of 1450×1450 mm. These machines allow us to handle a wide range of display sizes and configurations with ease, ensuring that each product is crafted to the highest standards. This meticulous approach helps us deliver displays that not only meet but exceed your expectations, making your brand stand out in any retail environment.

Die-Cutting, Folding & Gluing

Our advanced production facility is equipped with a comprehensive range of machinery to ensure precise and efficient processing of your cardboard displays. We use a variety of die-cutting machines, including:

1 Auto Die-Cutting Machine with a sheet size of 780×1060

1 Auto Die-Cutting Machine with a sheet size of 1040×1450

3 Semi-Auto Die-Cutting Machines with a sheet size of 1200×1620

For assembling and finishing, our facility features:

1 Auto Display Gluing Machine with a sheet size of 1080×1450

1 Auto Display Gluing Machine with a sheet size of 1300×1650

1 Auto Folding-Gluing Machine with a sheet size of 1650×1650

1 Auto Box Folding and Gluing Machine with a sheet size of 1100×1100

1 Auto Box Folding and Gluing Machine with a sheet size of 780×780

This diverse and sophisticated equipment allows us to produce high-quality, custom cardboard displays that perfectly meet your specifications. From precision die-cutting to seamless folding and gluing, we ensure each display is crafted to enhance your product's presence and appeal in the retail environment.

Digital Center

At our Digital Center, we leverage cutting-edge technology to ensure the highest quality in cardboard display production. Our facility is equipped with:

Epson 7910 Color Proof Digital Press: Capable of handling sheet sizes up to 610mm, this press delivers vibrant, accurate color proofs that bring your designs to life.

Zund G3 Digital Cutter: Known for its precision and versatility, this cutter handles various materials with ease, ensuring clean and accurate cuts for all your display needs.

Rzcrt-2516-Ⅱ Digital Cutter: This advanced cutter enhances our capabilities with its robust performance, perfect for intricate and detailed cutting tasks.

Rzcrt-1813E Digital Cutter: Ideal for high-speed and efficient cutting, this cutter complements our suite of tools, making it possible to meet tight deadlines without compromising on quality.

With this state-of-the-art equipment, we ensure that every cardboard display is crafted to meet your exact specifications, combining precision, speed, and exceptional quality to elevate your brand in the retail environment.

Testing Instrunment

At our facility, we ensure that every cardboard display meets the highest standards of quality and durability. To achieve this, we utilize advanced testing equipment, including:

1× ECT Board Tester: This tool measures the edge crush test (ECT) strength of our cardboard, ensuring it can withstand the pressures of handling and shipping.

1× Cartons, Cardboard Resistance Broken Meter Machine: This machine assesses the resistance of our cardboard materials to ensure they maintain their integrity under various conditions.

1× Drop Test Machine: We use this device to simulate drops and impacts, verifying that our displays are robust enough to survive the rigors of transport and use.

By leveraging these sophisticated tools, we guarantee that our cardboard displays are not only visually appealing but also engineered for exceptional performance and reliability.

FULFILLMENT-04

Efficient and Cost-Effective Display Solutions

Our approach to delivering cardboard displays is designed to streamline your operations and reduce costs. We take the extra step to palletize all components, so they arrive neatly packed on a pallet. This thoughtful arrangement allows your team to easily unpack and assemble the displays directly in your warehouse. Not only does this method save you significant packing costs, but it also simplifies the process, ensuring that your displays are ready to make an impact on the retail floor without any hassle. This efficient packing solution reflects our commitment to providing both quality and convenience in every aspect of our service..

Streamlined Solutions for Cardboard Displays

At our company, we understand that efficiency and cost-effectiveness are crucial in the cardboard display industry. That's why our approach to delivering cardboard displays is meticulously designed to streamline your operations and reduce costs. We go the extra mile by palletizing all components, ensuring they arrive neatly packed and ready for use. This thoughtful arrangement allows your team to easily unpack and assemble the displays directly in your warehouse.

Not only does this method significantly cut down on packing costs, but it also simplifies the entire process. With our efficient packing solution, your displays will be ready to make a powerful impact on the retail floor with minimal hassle. This dedication to both quality and convenience underscores our commitment to enhancing every aspect of our service, from production to delivery.

.

Co-pack Services

In the world of cardboard displays, we offer a comprehensive co-pack service designed to streamline your logistics and enhance efficiency. Our process begins with filling the already assembled displays with your products, ensuring they are packed securely into outer cartons. We then deliver all items to the designated address, making sure your products arrive in perfect condition.

Our assembly services include:

Storage of Displays and Goods: Secure and organized storage for both your displays and products.

Filling of Individual Displays: Carefully loading each display with the specified goods.

Placement on Small Pallets: Efficiently arranging filled displays on small pallets for easy handling.

Load and Packing on Standard Pallets: Consolidating smaller pallets onto standard-sized pallets for optimal shipping.

Transport Tests: Conducting rigorous transport tests to ensure durability and reliability during transit.

Storage of Ready Pallets: Keeping completed pallets in a secure location until shipment.

Shipping: Coordinating the final delivery to your specified location, ensuring a smooth and timely process.

Our co-pack services are designed to provide a seamless experience from assembly to delivery, ensuring your cardboard displays are ready to make an impact right out of the box

Delivery

We Ship Worldwide!

01

Strategically located near the Shenzhen port, we have streamlined access to global shipping for our POS displays. Whether you need ocean freight, air cargo, or express delivery, we tailor our shipping solutions to your specific requirements. Our established global partnerships ensure that your cardboard displays are delivered safely and efficiently to any corner of the world. With our commitment to timely and secure delivery, we guarantee that your products arrive exactly when and where you need them..